Pressure Die Casting

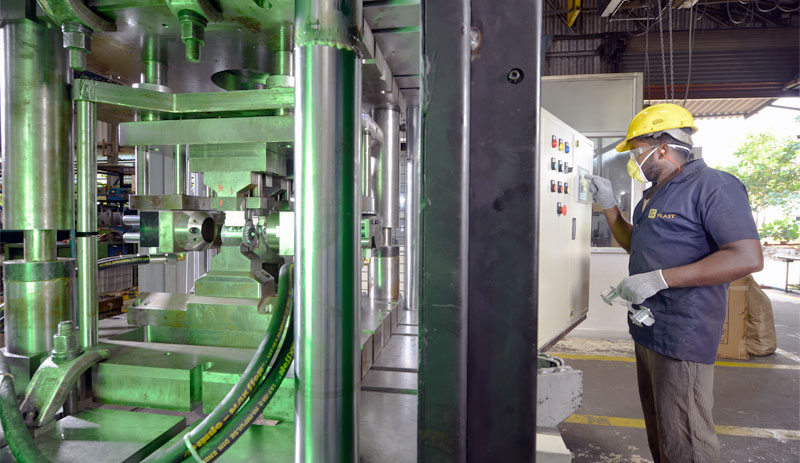

G-Plast's Die-Casting shop caters to Automotive, Computer Peripherals, Pneumatics, Aerospace, Textiles, Oil&Gas & General Engineering, etc... General Engineering Industries having capability to supply Aluminium & Zinc Die-Casting parts.

Casting, online trimming, secondary operations including vibro finishing, shot/sand blasting, ultrasonic cleaning, impregnation, leakt testing (upto 50bar), machining and painting/surface coating. Sub assemblies are also handled based on customer requirement..

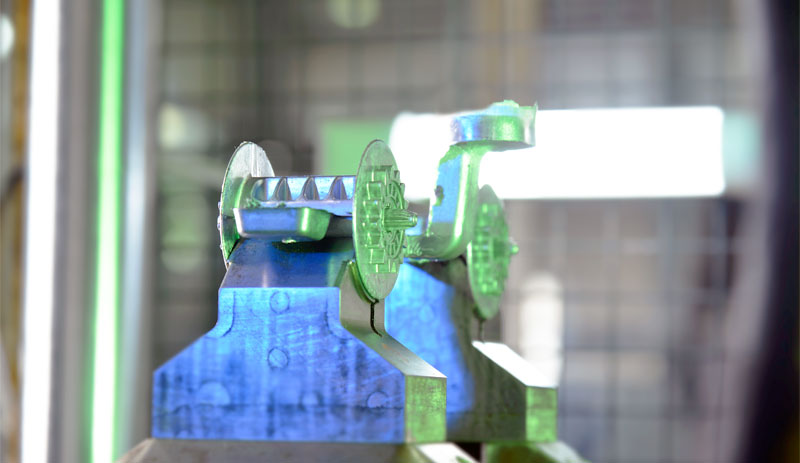

We are also exporting parts to Super-Markets directly. Complex Die Cast Components for engineering applications are mass-produced and supplied in Ready-to-assemble condition.

Equipped with 10 Machines ranging from 80T to 350T for Aluminium (Including Frech 350T). Frech 125T Hot Chamber machine supports processing of Zinc parts. Precision Machine Shop takes over the secondary machining to finish the parts.

COLD CHAMBER: (ALUMINIUM)

High Pressure Die-Casting parts are produced using FRECH, HMT, ZITAI & YOTA ranging from 80 Ton to 350 Ton.

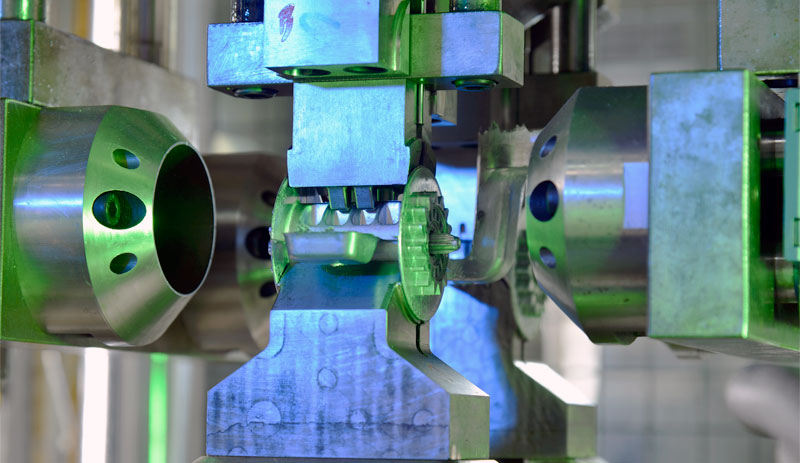

HOT CHAMBER: (ZINC)

G-Plast is a known source for processing Zinc, to have notable dimensional tolerances & high productivity achieved through FRECH 125 Ton – fully automatic machine.

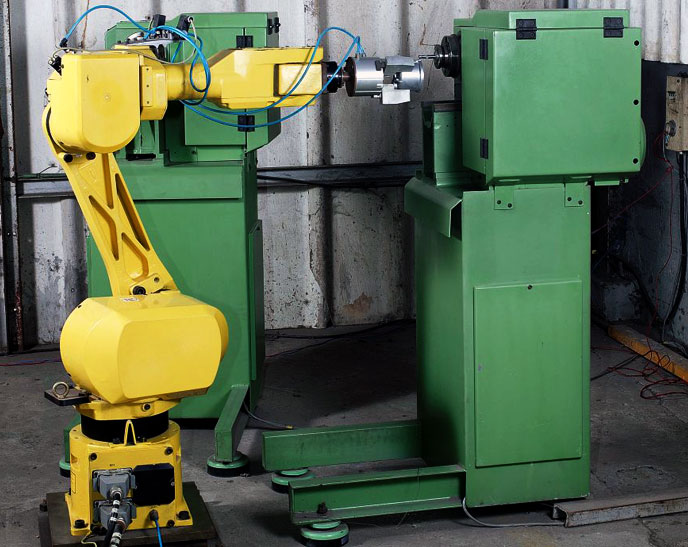

Robotic Assisted Manufacturing